| material: | Pure tungsten or Tungsten alloy |

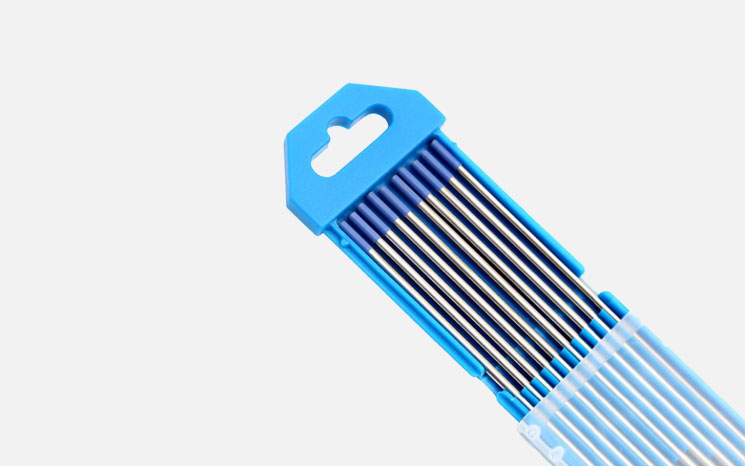

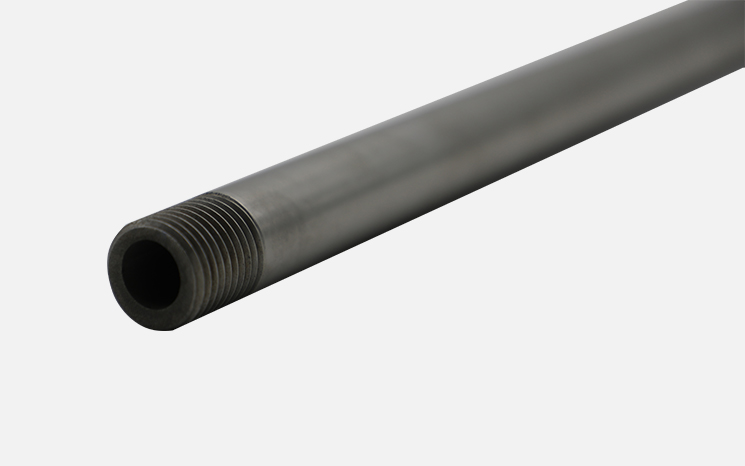

| Specification: | Ф(0.5-25)x150/175/178mm |

| Common size: Ф1.0/1.6/2.0/2.4/3.2/4.0/4.8/6.4*L150/175mm | |

| Customized size: As customer’s drawing | |

| Grade: | WT10 WT20 WT30 WT40 WC20 WL10 WL20 WZ3 WZ8 WP WY20 WX |

Pure tungsten electrode is most widely used in AC welding; When pure tungsten electrode is heated, the welding ball becomes sharp to provide a balanced waveform AC welding, and the arc is stable; Pure tungsten electrode also provides good arc stability for sine wave AC welding of aluminum and magnesium.

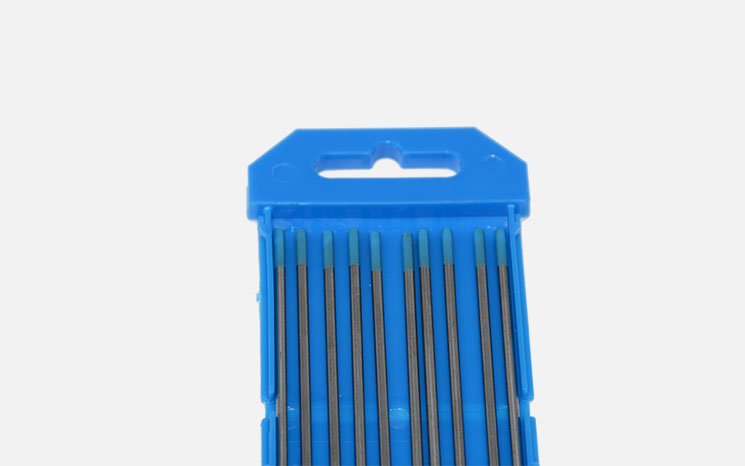

| type | brand | Color code | Chemical composition(%) | size (mm) | surface | features | ||

| Rare earth | impurity | W | ||||||

| Puretungsten | HW11 | green | - | ≤0.05 | 0.8~15 | D,E G,S | Pure tungsten electrode is only used as welding electrode under AC condition or as resistance welding electrode. | |

| Thorium tungsten | HWTh10 | yellow | 0.9~1.1ThO2 | ≤0.05 | margin | 0.8~15 | D,E G,S | Thorium tungsten electrode is the tungsten electrode with the best welding performance so far, and it occupies the highest market share in the world. However, because thorium tungsten electrode |

| HWTh20 | red | 1.8~2.2ThO2 | ≤0.05 | margin | 0.8~15 | |||

| Lanthanated tungsten | HWLa10 | black | 0.8~1.2La2O3 | ≤0.05 | margin | 0.8~15 | D,E G,S | Non-radioactive, excellent electrical conductivity and welding ability, high current carrying capacity, lowest burn area ratio, replacing thorium tungsten electrode, mainly used for DC welding. |

You can enter your detailed information and needs in the following forms ,such as your name, phone NO.,Email address, Once received your message we will contact you as soon as possible.

Copyright © Luoyang Combat Tungsten & Molybdenum Material Co., Ltd.